3.15 Special Plan for Consumer Rights Day--Second Season of Gu Rong Selection

In the last issue, we published an article on the "seven drops and eight liters" of Gu rough sorting, which has received extensive attention from many friends in the industry. At the request of many old irons, in order to let more friends see the essence of Gu Rong sorting, the long-awaited sequel to the big reveal is here. The editor will continue to reveal the inside story of Gu Rong sorting for everyone. There are easter eggs at the end of the article.

The origin of grain sorting process

Speaking of the grain sorting process, we have to mention an authoritative expert in the rice processing industry, chief engineer Xie Jian, the drafter of the National Grain Wuhan Science Research and Design Institute and the drafter of the new GB/T1354-2018 rice national standard. Xie always took the lead in putting forward the idea of grain sorting in the rice processing industry. With the active promotion of President Xie, the sorting industry began to pay attention to this application scenario, and grain sorting came into being. The new process revolution solves many problems in conventional processes and creates unprecedented user value.

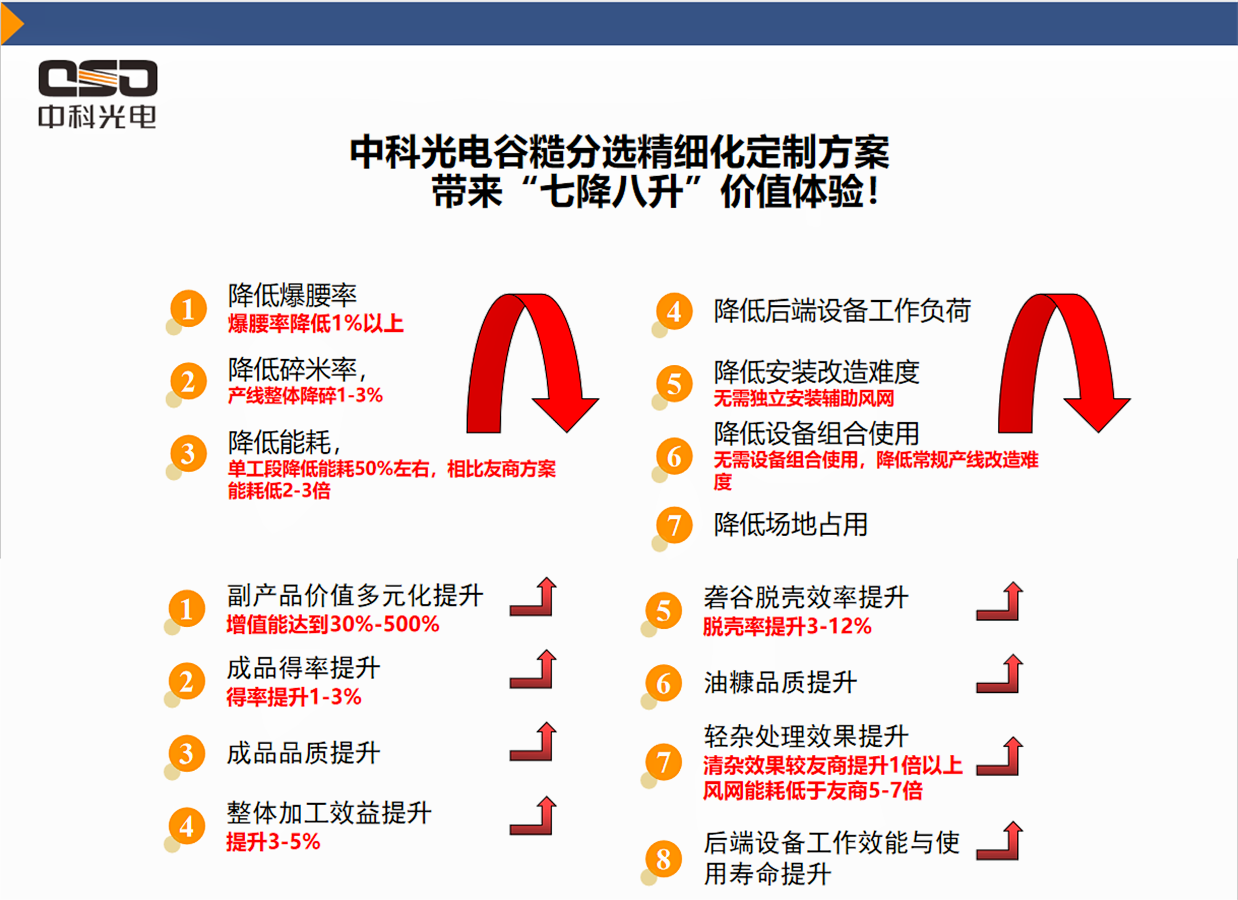

Zhongke Valley Rough Sorting: Review of the Value of "Seven Drops and Eight Liters"

The core word of this reveal: the color selection of Gu Rong sorting!

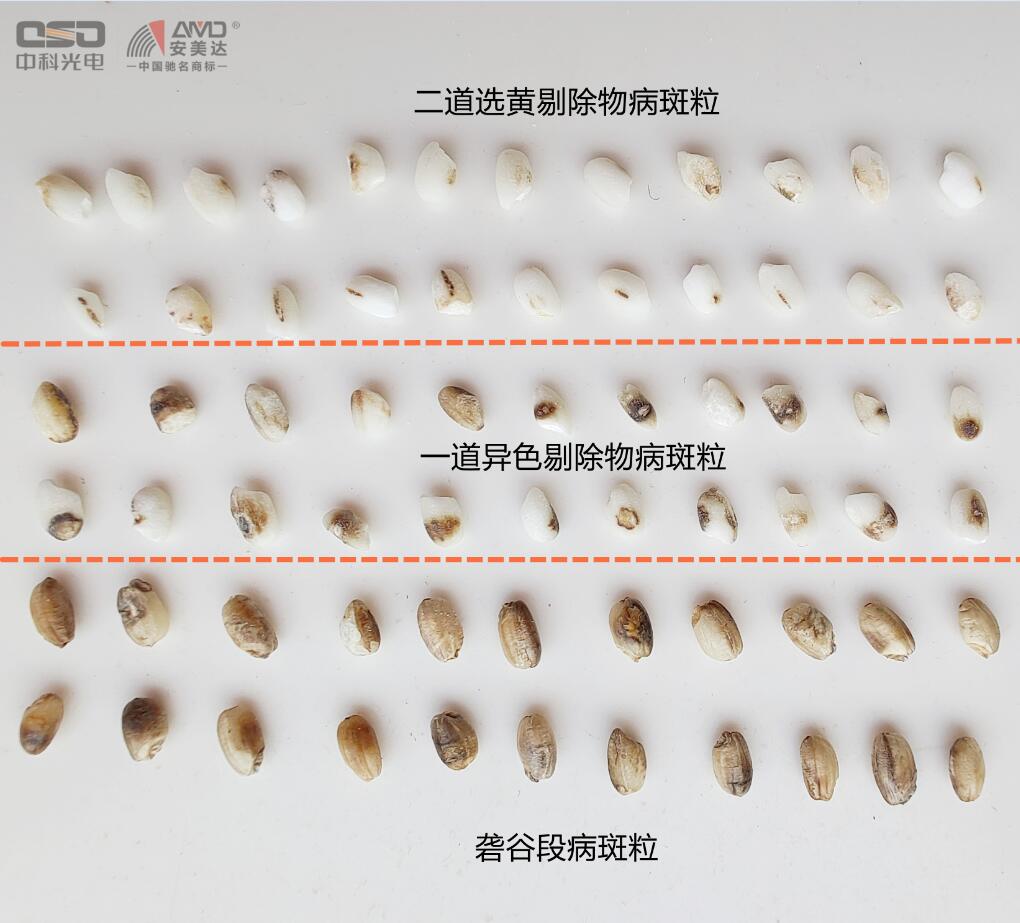

After the birth of the rice grain sorting process, it has been over-packaged by many friends and businessmen, and many new words that have never been heard of have emerged one after another. Many rice processing companies are also confused and do not know how to choose the right products. The first use of grain sorting is color sorting, because the color difference of the selected materials is obvious, and the sorting difficulty is higher than that of rice sorting. Color difference legend of sorting materials:

I believe that many friends have heard some sorting industry friends and businessmen publicize "select red to protect red" and "select green to protect green". In fact, these are all publicity stunts. A simple explanation is to remove the variegated red brown rice and keep the pure red brown rice as the finished product. It is a sorting method for purifying red brown rice.

The so-called "selecting green and protecting green" is also the same principle. Eliminate the powdery grains in brown rice and keep the gelatinous grains. It is also the category of color selection, and the high-value gelatinous grains are retained. See the legend:

"Rough in the grain", "Rough in the grain", "Rice in the rice", "The grain in the grain" are all the same, but they are actually the category of color selection, just changed to a name that is not common to everyone. See the legend:

Take our brown rice sorted by grain as an example. The texture of red brown rice is hard and wear-resistant. In the conventional process of the rice production line, there will be three distinct external forms at different stages. The diagram is as follows:

Friends who do rice processing know that red glutinous rice is more difficult to sort in daily life, and if the selection is not clean, it will affect the appearance and taste of rice. This is related to the deep back groove and wear resistance of red brown rice. The new process of grain roughness sorting in advance will bring about a significant improvement in the efficiency of the back-end sorting equipment, and the quality of the final product and the whiteness of the finished rice will also be improved.

The color difference of the diseased grains selected by the conventional color is very obvious in the grain roughness stage. The grain roughness selection technology can be used for precise separation, so as to reduce the impact on the back-end process and improve the work efficiency of the back-end sorting equipment. The sorting task of the terminal is pre-positioned. Taking the glutinous rice lesions as an example, the appearance in our processing process is as follows:

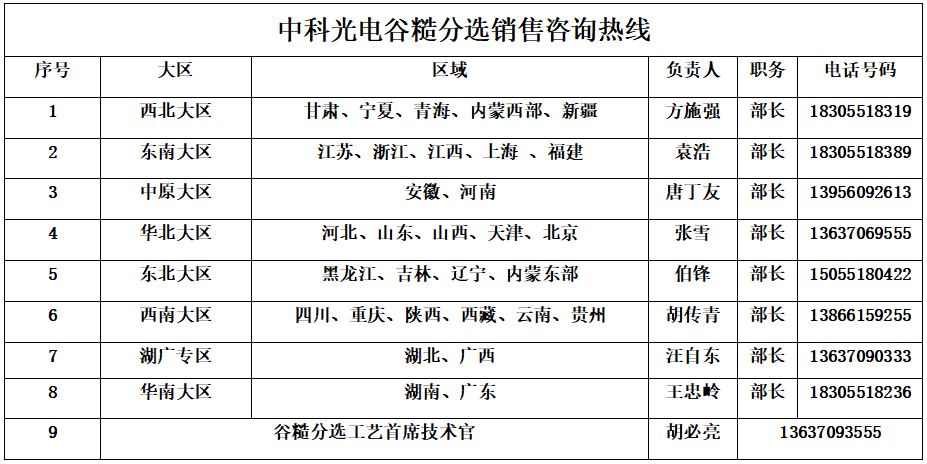

The book is short and long, and today's secret is here. The content of this issue is to let the rice industry friends see the essence of grain sorting through systematic explanations. Everyone avoids excessive conceptual speculation and confusion, and reasonably chooses grain sorting products. You can contact the regional sales leaders! Please continue to pay attention to us. In the next issue, we will reveal the shape selection technology used in the grain sorting.

Today, let's demystify the concept of "quality selection", so what is "quality selection"?

When it comes to this concept, it is actually inseparable from the progress of sorting technology. The sorting technology started from the earliest photoelectric sorting and gradually developed to the present with color recognition, shape recognition (similar to the selection of varieties), infrared sorting (material selection). A fusion of technologies such as sorting) and smart sorting (referring to the intelligence level of sorting equipment). Sorting by a single color cannot comprehensively summarize the attributes of our products, and the concept of quality control and sorting came into being, which is the origin of "quality selection".

At present, the products sold in the sorting industry all have mature color sorting, shape sorting, and material sorting technologies, and at the same time have intelligent functions. The so-called "quality selection" is just a packaging word.

Website Homepage

Website Homepage Product

Product Service

Service News

News About

About Contact

Contact