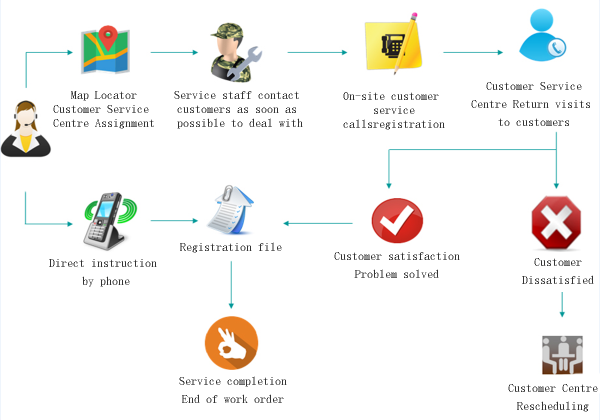

Zhongke Optoelectronics Always adhere to the customer demand as the center, adhering to the "we are by your side" service concept, and strive to build a "remote service as the guide, on-site service as the center, headquarters support as the backing" whole network after-sales service system. Relying on the call center and after-sales service outlets, we will implement overtime and value-added services to build a new service system of industry 4.0.

Each shift: use air gun to clean the channel and sorting room before maintenance, start the machine for preheating, and self test the spray valve of the system

Attention - when cleaning the sorting room with the air gun, never blow the air gun mouth towards the nozzle, so as to prevent the sediment from blowing into the air pipe of the nozzle and causing artificial blockage. During the operation, inspect the working state of the color sorter (including working indication and alarm indication) and the action of the spray valve;

During the operation, inspect the working state of the color sorter (including working indication and alarm indication) and the action of the spray valve; Inspect whether the air compressor, air pressure and sound are abnormal; The air compressor should drain water at least 3 times per shift (increase the number of times in summer); After 10 minutes of shutdown, turn off the color sorter software, then turn off the power switch and the air compressor switch, and the air compressor discharges water; Use air gun to clean up the sediment in nozzle plate, guide plate, channel and separation chamber; Use air gun to clean the vibrator, the inner side of the body, the hopper and the dust brush. Monthly: check the filter element; Clean the filter element once a quarter and replace it once a year (regular cleaning or replacement of the filter element can effectively prolong the service life of the nozzle and directly affect the effect of your machine). Check the cleanliness of the cleaning brush. If the brush skin is worn and cannot achieve the cleaning effect, replace it. Every six months: fill air compressor oil once

Keeping the machine clean is very important to maintain the environmental sanitation and the working efficiency of the machine. When the machine becomes dirty, the efficiency of color selection will gradually decrease. When the dust is attached to the lens glass, the effect of color selection will be directly affected. At the same time, the machine is prone to failure when it is working with dust. When you are cleaning the machine, you can check and find potential problems.

Important matters: 1. Do not use wool thread or corrosive agent on any parts of the machine to prevent contamination of the materials to be color selected; 2. Pay special attention not to damage the special surface of vibrator, channel, sorting room or touch screen. Clean the sorting room glass (1) wipe the outside glass of the sorting room with a clean soft cloth dipped in alcohol( 2) The soft cloth dipped in alcohol can also be clamped between the cleaning brush and the glass, and then the cleaning procedure can be run to obtain better cleaning effect. Cleaning channel (1) when installing the color sorter, please do not remove the protective board to avoid welding slag and paint damage to the channel( 2) Use a clean soft cloth to wipe the channel (3), and do not use sharp objects to wipe or touch the channel, so as to avoid scratching the channel and causing material jumping

Clean the ash cleaning cylinder guide rail (1) and wipe the cylinder guide rail with a clean soft cloth( 2) Clean the dust on both sides of the cylinder slider with an air gun after work. Clean the background plate (1), open the sorting chamber box, and carefully wipe the background plate with a clean soft cloth dipped in alcohol. Ash cleaning brush replacement (1) pull up the limit plates on both sides of the ash cleaning brush, hold the adjusting frame and rotate it away from the glass to take out the ash cleaning brush downward. Air filter element replacement (1) screw off the four screws on the upper side of the filter( 2) Open the upper cover of the filter and take out the filter element for cleaning or replacement. Please pay attention to the installation direction of the filter element for cleaning and replacement.

Cause of failure: foreign matter or damage in the valve, temperature lower than 5 ° C, water vapor in the valve.

Solution: when the spray valve works normally, there are certain requirements for the flowing gas. If the gas contains too much moisture or other impurities, it will cause the leakage of the spray valve. When the spray valve leaks, color selection will reduce the effect of color selection and affect the stability of the gas path. Once there is air leakage in the spray valve, it indicates that the spray valve has been damaged which is difficult for customers to repair. It is necessary to contact the after-sales service department of our company to send professionals to replace the damaged spray valve.

Cause of failure: poor contact between valve plug and spray valve seat, broken wire of valve core, open circuit of control circuit.

Solution: there are several reasons that cause the spray valve not to work. Customers can remove the fault step by step according to the following steps. First, check the connection between the spray valve circuit and the spray valve to see if there is any connector falling off. If so, please disconnect the power supply of the whole machine first, and then start the machine for inspection, Eliminate the possibility of failure caused by poor contact between valve joint and spray valve base. When the above connection is normal, it is necessary to detect the fault of the driving circuit of the spray valve (including the fuse on the circuit board), and strictly abide by the operation safety during self inspection, or contact the after-sales service department of our company to send professional personnel to deal with the damaged spray valve or driving circuit.

Cause of failure: the air pressure is too low

Solution: check whether the working air pressure of the color sorter is normal, and check whether the air pressure pipe switch is opened.